Since the establishment of the company in 1990, our primary focus has been on researching new methods and developing instruments for materials science and engineering. This effort is driven by our in-house R&D team in collaboration with academic partners from select universities and research institutions.

Technoorg Linda is fully committed to serving the global scientific community with the highest-quality sample preparation tools designed for electron microscopy analysis. Our customers include industrial, governmental, and academic research departments and laboratories, covering the full spectrum of materials science instrumentation users. Recognized as a trusted name within the global scientific community, Technoorg Linda is synonymous with precision instruments and world-leading sample preparation techniques.

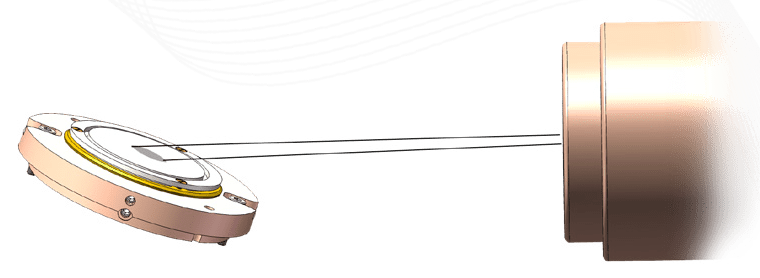

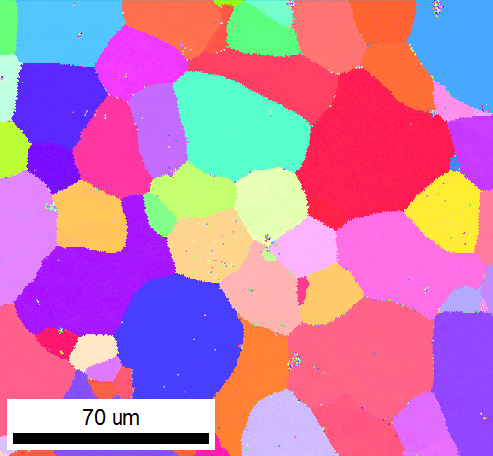

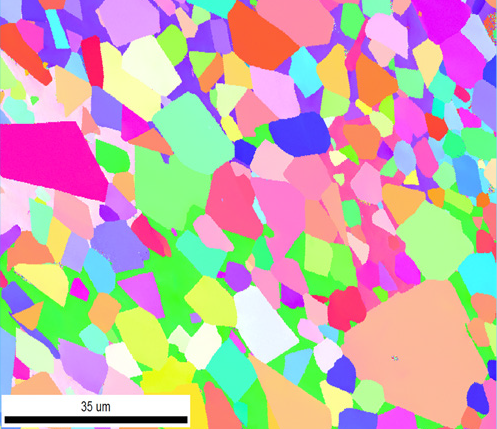

SEMPRE P SMAR T is an award-winning ion milling solution designed for high-precision SEM and EB SD sample preparation. The device is equipped with a high-energy and, optionally, a low-energy argon ion source. Ion polishing allows for the improvement and cleaning of mechanically polished SEM samples and the preparation of damage- free surfaces for EBSD analysis . Outstanding cross- sectional results and precision are achieved even in demanding and sensitive cases , such as semiconductor testing and investigation o f Li – ion battery separator membranes.

KEY FEATURES OF SEMPREP SMART

- AI-assisted, easy-to-use operation

- Highly automated workflow

- Extreme-precision cross-sectioning

- Intuitive control software

- Wide range of sample dimensions

- High-energy ion source for rapid milling

- Optional low-energy ion source for ultimate polishing results

- Vacuum sample transfer capability

- Automated liquid nitrogen or easy-to-use Peltier sample cooling

- Widest energy range on the market

POLISHING WITH AR-ION BEAM

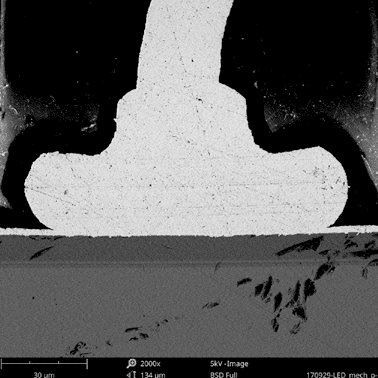

surface of an LED electrode

sasas

A r-ion polishing.

asdsd

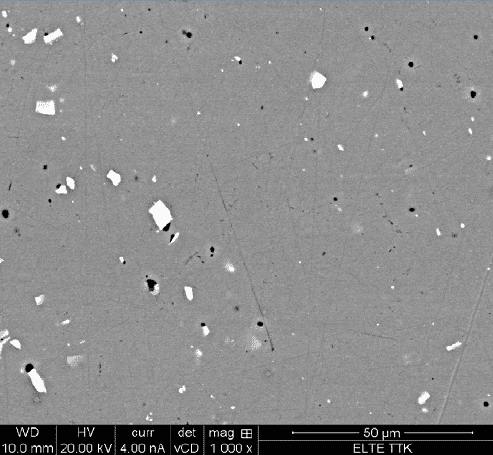

after mechanical polishing.

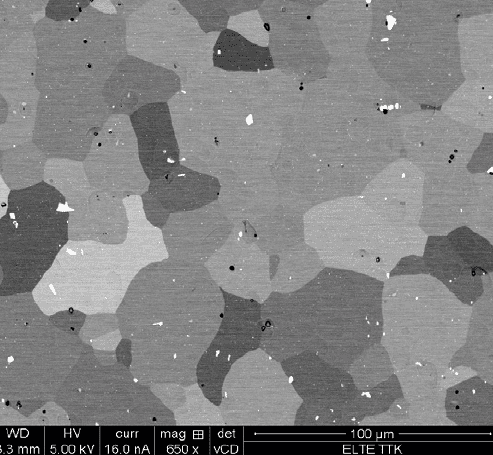

after Ar-ion polishing.

the Al plate after Ar-ion polishing.

xaxax

zaxxa

adsdffsdfdf

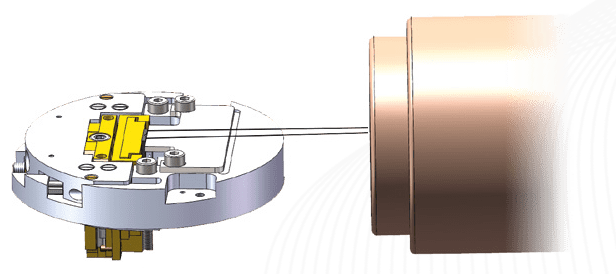

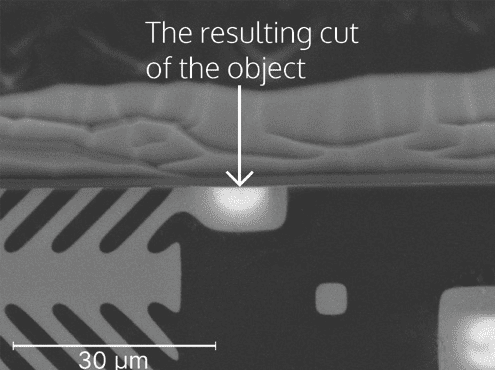

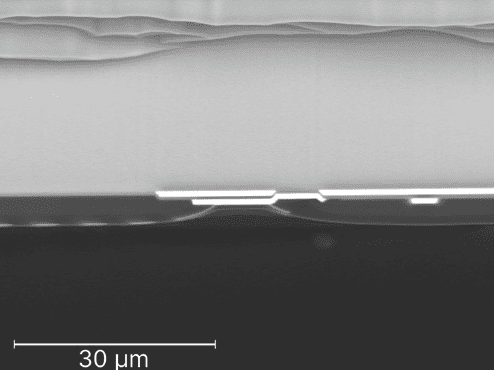

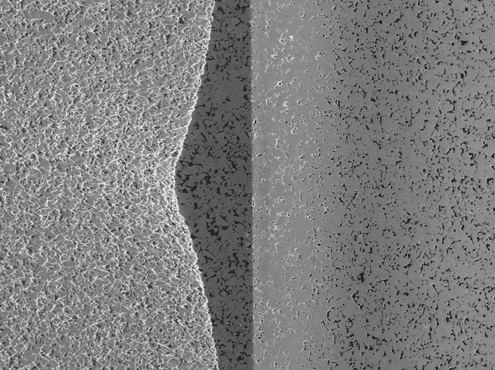

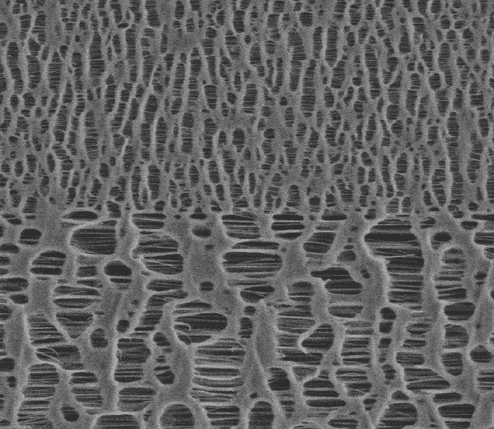

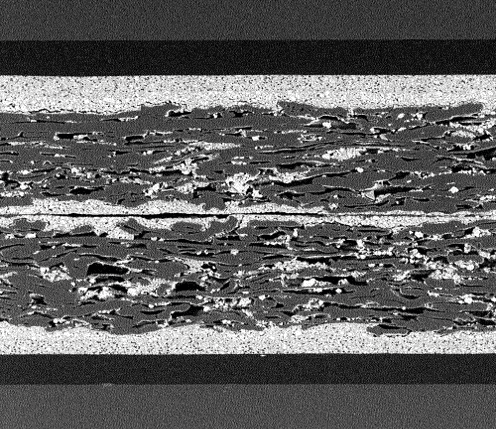

90° CROSS-SECTIONAL CUT AND 30° SLOPE CUT

Cross-sectional cutting for accurate measurements and real cross-section investigations. 30° slope cutting for EBSD-quality surfaces anywhere inside the sample.

The accuracy of the cutting

position is ±1 μm.

surface behind the spot.

carbide (WC-Co) sample.

multilayer battery separator

membrane, prepared at room

temperature.

laminated paper with liquid

nitrogen cooling.

SPECIFICATIONS

Ion sources

- High-energy ion source operating up to 16 keV

- Maximum milling rate: >500 μm/h

- Optional low-energy source

Sample size

Slope cutting (30°) and cross-sectional cutting (90°)

sample holders:

- 30° holder: max. 35 mm (l) x 16 mm (w) x 4.5 mm (th)

- 90° holder: max. 18.6 mm (l) x 16 mm (w) x 6 mm (th)

Sample holder for surface polishing (EBSD) with three

different head types:

- Flat head type: max. Ø50 mm x 4 mm

- Standard type: max. Ø32 mm x 15 mm

- Hollow type : max. Ø25 mm x 23 mm

Sample stage

- Tilting: +/- 30°

- Rotation: 360°

- Oscillation: +/- 1° to +/- 360°

zvcd

Sample cooling (optional)

LN2 cooling or Peltier cooling

Vacuum system

Oil-free diaphragm and turbomolecular pumps

Gas supply system

99.999% purity argon working gas, flow controlled

with a needle valve, optional dry nitrogen venting

Turbomolecular pump

Pfeiffer HiPace 80 Neo

Imaging system

High-resolution CMOS camera with magnification-

tracing measurement capabilities within the live image

Computer control

Easy-to-use graphical interface with ergonomic,

built-in multi-touch screen, automated ion source

operation, and stage position calibration

xaxax

zaxxa

adsdffsdfdf